Technical information

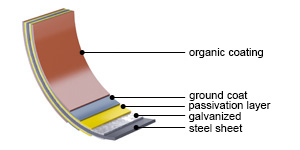

Galeco STAL system is made of the best quality coated steel. It is provided with four protective layers: zinc, passivation coat, primer, and organic coat. It is the only TOTAL PROTECTIVE SYSTEM FOR GUTTERS AND FALL PIPES as foiling and pipe internal seam guarantee high aesthetics quality without any scratches.

Materials

Galeco STAL System is made of high-quality coated steel. High durability of plates is ensured through the application of additional 4 protective layers which prevent the material against adverse weather conditions. Steel core thickness is 0.6 mm. It is double, zinc-coated, passivated, and coated with organic protective aesthetic layer.

Colour scheme

STAL

| Gutter type / Pipe diameter | |||||

|---|---|---|---|---|---|

| Colour RAL | 120/90 | 135/90 | 135/100 | 150/100 | 150/120 |

| A Graphite (~ RAL 7015) | |||||

| D Brick (~ RAL 8004) | |||||

| V Dark brown (~ RAL 8019) | |||||

| E Chocolate brown (~ RAL 8017) | |||||

| W White (~ RAL 9003) | |||||

| B Black (~ RAL 9005) | |||||

| P Dark red (~ RAL 3009) | |||||

STAL SATIN

| Gutter type / Pipe diameter | |||||

|---|---|---|---|---|---|

| Colour RAL | 120/90 | 135/90 | 135/100 | 150/100 | 150/120 |

| Y Graphite SATIN (~RAL 7016) | |||||

| U Black SATIN (~RAL 9005) | |||||

| K Chocolate brown SATIN (~RAL 8017) | |||||

STAL METALIC

| Gutter type / Pipe diameter | |||||

|---|---|---|---|---|---|

| Colour RAL | 120/90 | 135/90 | 135/100 | 150/100 | 150/120 |

| H Copper (~ RAL 8007) | |||||

| G Antracyt (~ RAL 9007) | |||||

| I Silver (~ RAL 9006) | |||||

Efficiency table

Following table determines Galeco STAL system efficiency in accordance with the placement of the fall pipe.

| Gutter type / Pipe diameter | |||||

|---|---|---|---|---|---|

| Positions of the downpipe | 120/90 | 135/90 | 135/100 | 150/100 | 150/120 |

|

60 m2 |

110 m2 |

110 m2 |

150 m2 |

150 m2 |

|

120 m2 |

220 m2 |

220 m2 |

300 m2 |

300 m2 |

Standards

Polska Norma PN-EN 612 for gutters, pipes and profiles - May 2006, „Roof gutters made of metal sheets with round reinforced front side rim and overlapped fall pipes”.

Polska Norma PN-EN 1462 - April 2006, „Handles for roof gutters. Requirements and examinations”.

Our own declarations have been confirmed through testing that were carried out by Building Research Institute: testing reports no.:

LOW/019.1/2007, LOW/019.2/2007, LOW/108.1/2008, LOW-537.1/2009.

Corrosion Classes

| Class | Corrosion | Enviroment description |

|---|---|---|

| C1 | VERY LOW | Heated locations with dry air and insignificant pollution level, e.g. offices, schools and hotels. |

| C2 | LOW |

Locations with low air pollution level. Non-heated locations with temperature and humidity fluctuations characterised by low frequency condensation and low level of air pollution, e.g. fitness centres, warehouses. |

| C3 | MODERATE |

Locations in which salt or air pollutions are present at a moderate level. Urban locations, light industry zones and areas that are subject to a certain impact from the waterside. These are locations with moderate humidity and those in which some air pollutants are present such as digester houses, creameries, laundries, etc. |

| C4 | HIGH |

Locations in which salt or air pollutions are present at a moderate level. Industrial and waterside areas. Locations with air high humidity and high pollution originating from industrial processes, e.g. chemical industry, indoor swimming pools, shipyards. |